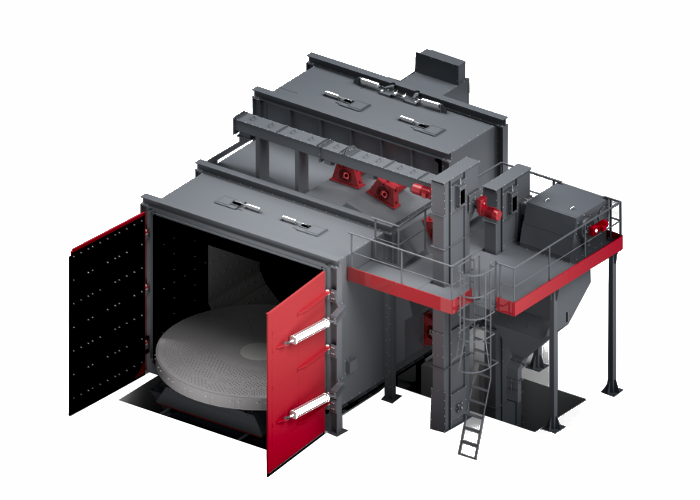

Bogie table shot blasting machine is designed for cleaning large and heavy workpieces of complicated shapes produced in small series or individual production.

Transport bogie with a rotary table enables easy loading / unloading and safe transport of workpieces to and from the machine. The workpieces are loaded onto the perforated rotary work table outside the blasting chamber by crane and then by bogie transported into the machine.

It is desirable to cover as much of the table surface as possible with the workpieces. During the shotblasting, the workpieces on the rotary table move through the jets of blasting media of the blasting wheels that are installed at different angles, which allows greater efficiency.

You must turn over the workpieces and then repeat the shot blasting process or in some cases, additional air blasting is performed manually by an operator. With this, we achieve complete cleaning of all areas of the workpiece.

The housing of shot blasting machine is made of sheet metal and profiles in three welded segments, which together form a chamber. The interior of shot blasting chamber is additionally protected by wear-resistant shields made of manganese steel. The system for continuous return and cleaning of the abrasive, together with efficient blasting wheels made of wear-resistant materials, enable the high performance of the shot blasting machine.