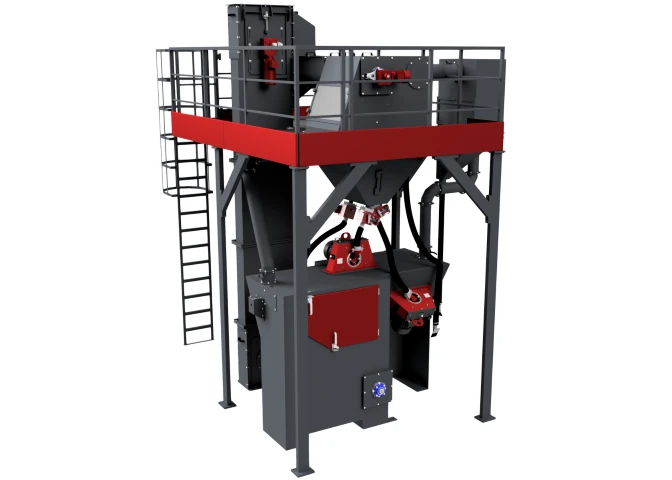

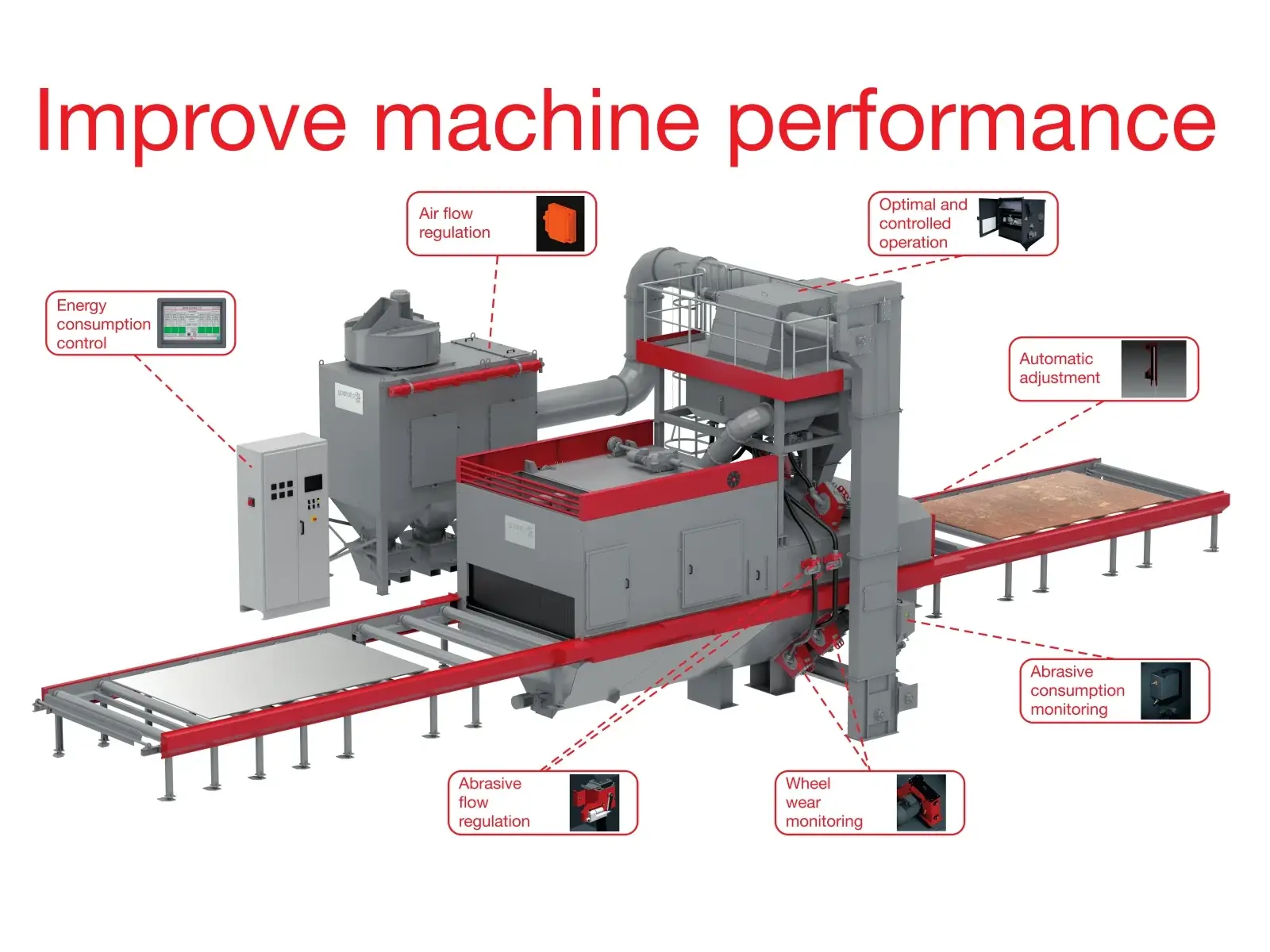

Continuous wire descaling shot blasting machine is designed for continuous removal of scales and shotblasting of wire / bars of various shapes (round, square or hexagonal), cross-section from 5 to 80 mm, and for preparation for further operations such as drawing, rolling, electroplating, etc.

Options before / after shotblasting:

- Installation in-line

- Loading of workpieces

- Roller guidance at the entrance / exit

- Handling of workpieces

- Cutting of workpieces

- Painting

- Packing of workpieces

The machine has guide plates made of hard wear-resistant material (hardened tool steel) that narrow the abrasive jet (by rebound) from the normal width of 60 mm to the width of the workpiece. This directs the energy of the abrasive to the workpiece and achieves the maximum utilization of the machine.

Machine versions with 3, 4 or 6 blasting wheels are available. The number and power of the blasting wheels is determined according to the thickness of the wire / bars and the speed of the wire / bars through the machine.

The inlet and outlet sealing chamber is sealed with screens that keep the abrasive in the shot blasting machine. The robust housing of the machine is protected by wear-resistant manganese steel plates in the shotblasting chamber.