Rotary table shot blasting machine is designed to process workpieces of various shapes and dimensions, castings, forgings, pressed parts, parts made of steel or non-ferrous metals, and parts of fragile materials. They are particularly suitable for use in small series or individual production.

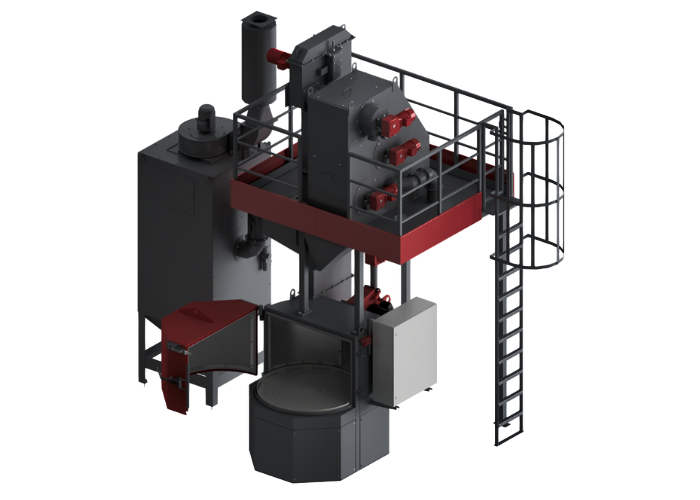

All rotary table shot blasting machines are equipped with large doors that are easy to use for quick loading. The workpieces are loaded onto a perforated rotary table.

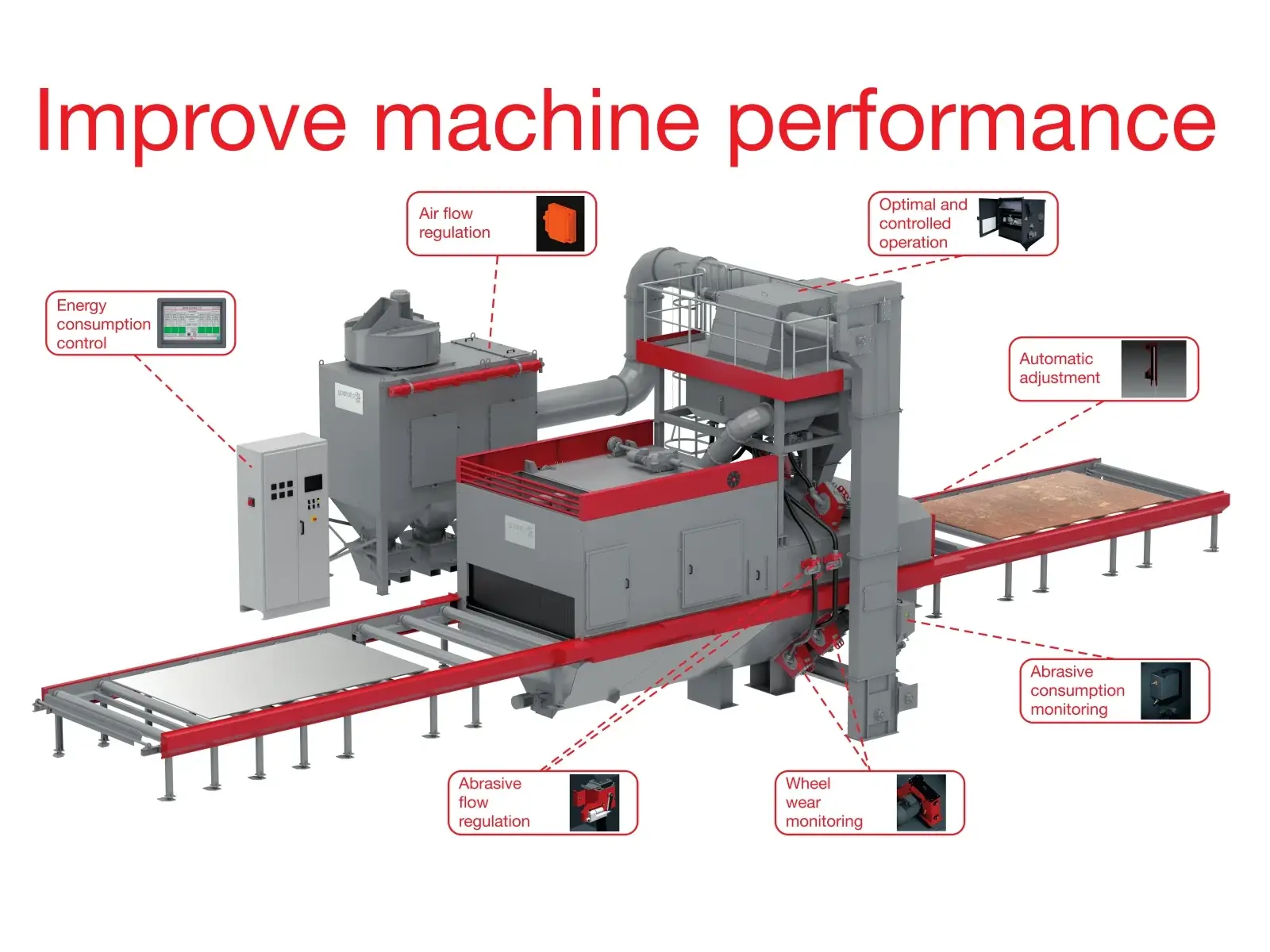

The housing of the shot blasting machine is robust and protected by wear-resistant materials. High efficiency of the rotary table machine is enabled by the continuous abrasive handling and reclamations system for continued returning and cleaning of blasting media, along with efficient blasting wheels made from wear-resistant materials.

The rotary table shot blasting machine has installed one or two blasting wheels, depending on the size of the model. Standard working table sizes are from 650 mm to 2,400 mm and are suitable for workpieces to a maximum height of 1,500 mm.

Gostol TST has developed special types of rotary table shot blasting machine. The machine type K3-D has a table mounted on the door of the shot blasting machine, which allows loading with a lift or forklift over the entire surface of the table. The shot blasting machine type K3-D-2 has two tables that enable simultaneous shotblasting of workpieces in the machine and loading or turning of workpieces in front of the machine.