The website uses cookies to make the website work properly and improve your experience. More information can be found in Cookie policy.

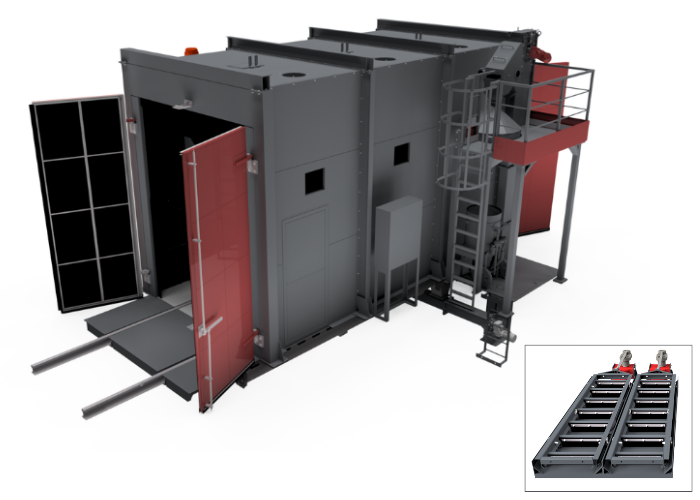

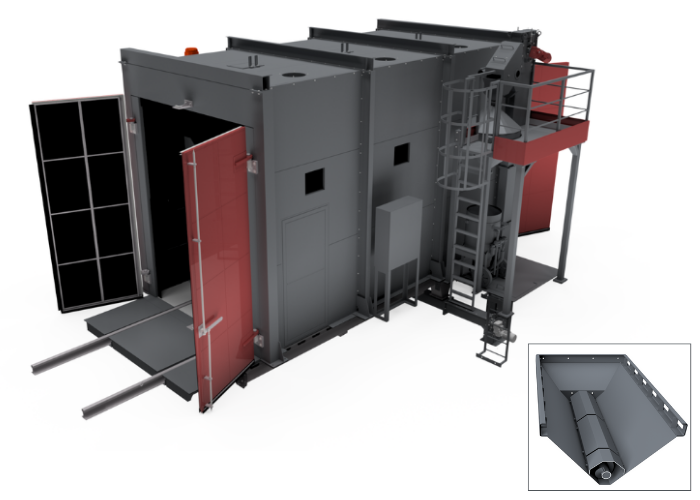

Sandblasting Chambers

Sandblasting is known as environmentally friendly and cost-effective process. The blasting chamber or blast room is a large chamber and a complete device with blasting system, abrasive recovery system, dust collector and abrasive cleaner. Gostol TST blasting chambers are well-designed and ensure controlled and clean environment. Whether you need to remove existing coatings or prepare surfaces for subsequent treatments, our blasting chambers are the ideal solution for your needs.