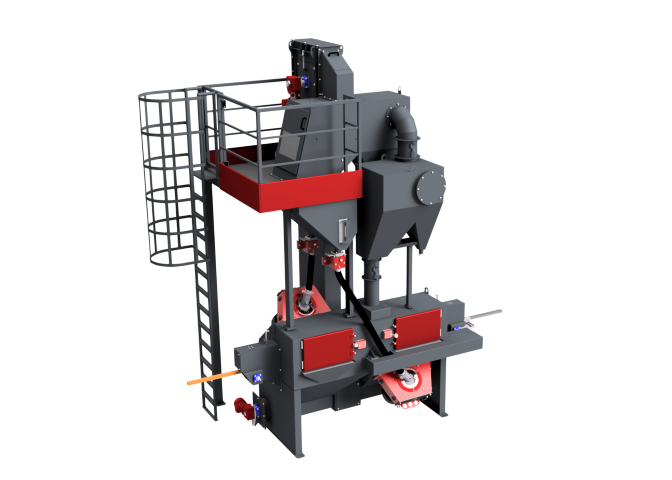

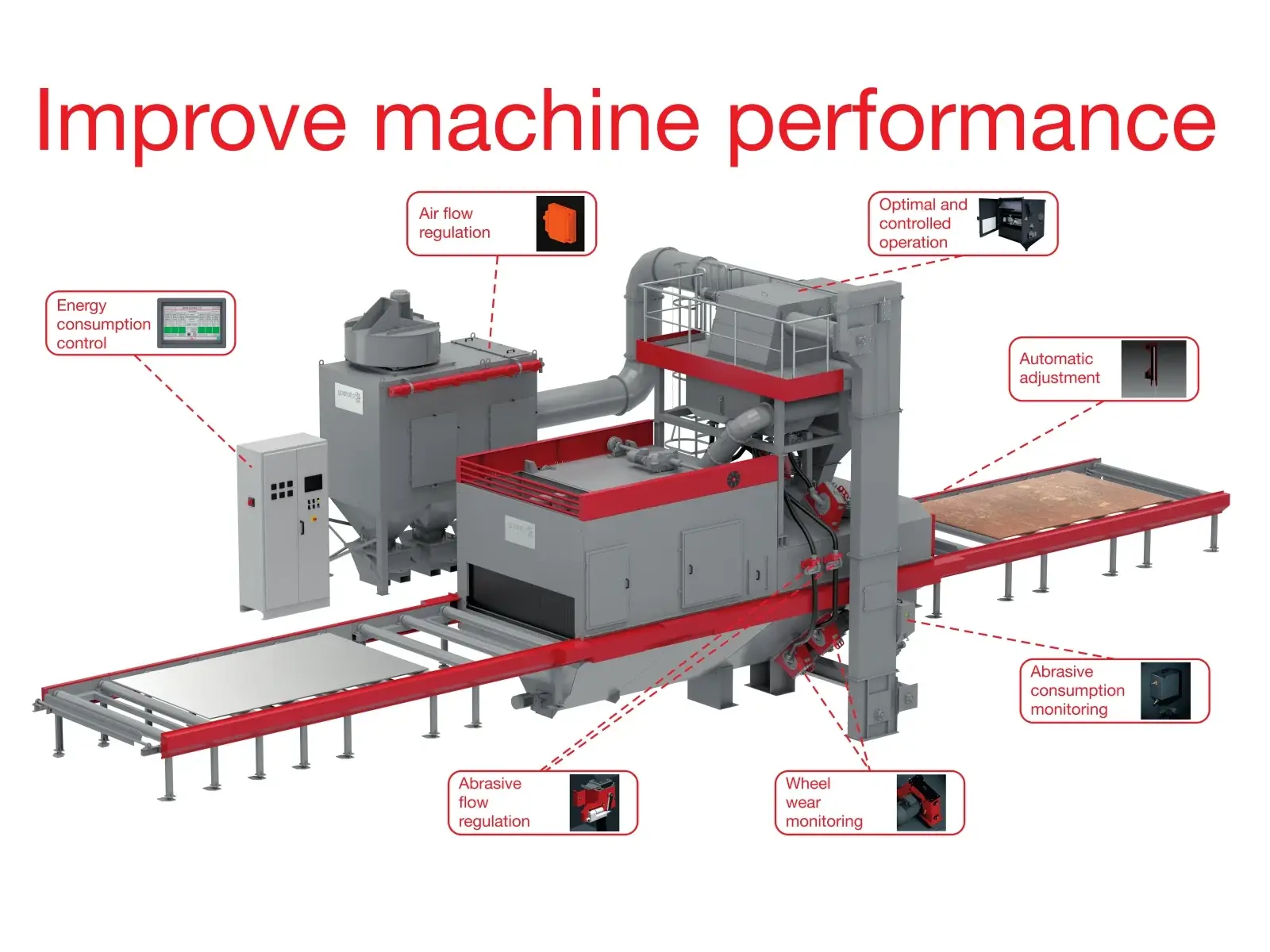

Shot blasting machine for flat bars type PL is used for shot blasting flat bars of various dimensions and lengths. It is suitable for medium-sized capacities.

The machine is equipped with a horizontal manipulator for automated transport of flat steels to the machine and then through the machine via conical rollers.

Bars are loaded on the loading device. The cross conveyor adds the bars to the roller conveyor automatically, and the press wheel presses the bars onto the rollers. After shotblasting, it automatically unloads them from the roller conveyor. The width of guide profile on the roller conveyor can be changed depending on the size (width) of the bar.

In the machine, there are directional flaps, made of wear-resistant steel, which direct the jet to the workpieces, so that the energy of the blasting wheels is used to the maximum. The input switch automatically turns on / turns off shotblasting. The blasting wheels shotblast only the workpiece, which reduces machine wear and energy consumption to a minimum. The machine is robust, the shot blasting part is made of manganese steel and additionally protected by wear-resistant shields.