| Machine type | VZ-C-450x1600 | VZ-C-150x350 | VZ-L-250x300 | VZ-L-350x500 |

| Technological purpose for shotblasting | shotpeening of coil compression springs | shotpeening of coil compression springs | shotpeening of leaf springs | shotpeening of leaf springs in tension |

| Max spring diameter (mm) | 450 | 140 | / | / |

| Min spring diameter (mm) | 100 | 80 | / | / |

| Max spring length (mm) | 1600 | 350 | / | / |

| Min spring length (mm) | 150 | 150 | / | / |

| Working width (mm) | / | / | 250 | 350 |

| Working height (mm) | / | / | 300 | 500 |

| Blasting wheel diameter (mm) | 380 | 380 | 380 | 380 |

| Blasting wheel power (kW) | 2 x 37 | 2 x 30 | 2 x 37 | 4 x 37 |

| Passing speed (m/min) | 1.0 - 8.0 | 1.0 - 8.0 | 0.5 - 5.0 | 1.0 - 8.0 |

| Transport system | longitudinal rollers with drag chain | longitudinal rollers with drag chain | belt conveyor | roller conveyor |

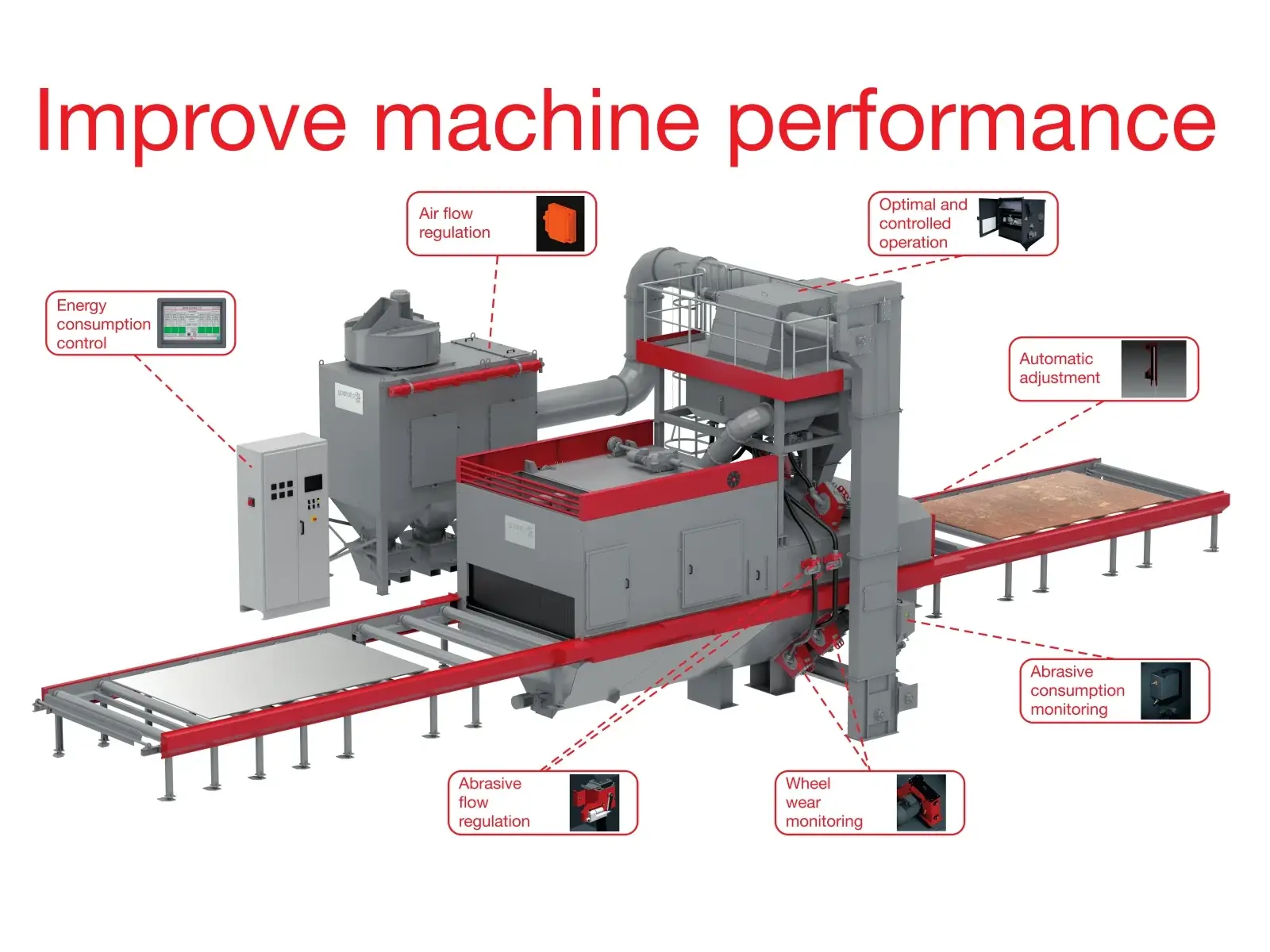

For additional information on different dimensions of shot blasting machine and the number of blasting wheels, please contact us. The machines listed are only an example of standard machines, but other adaptations and variants are available.