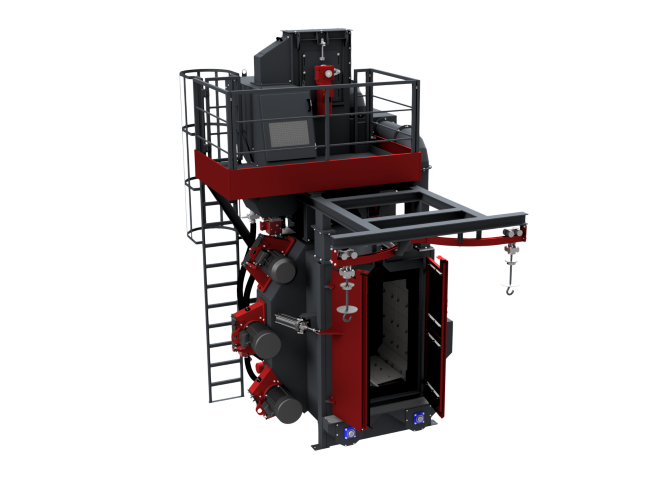

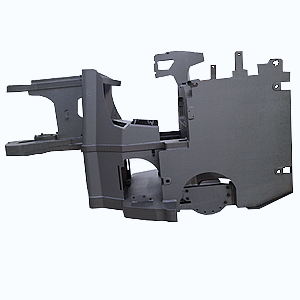

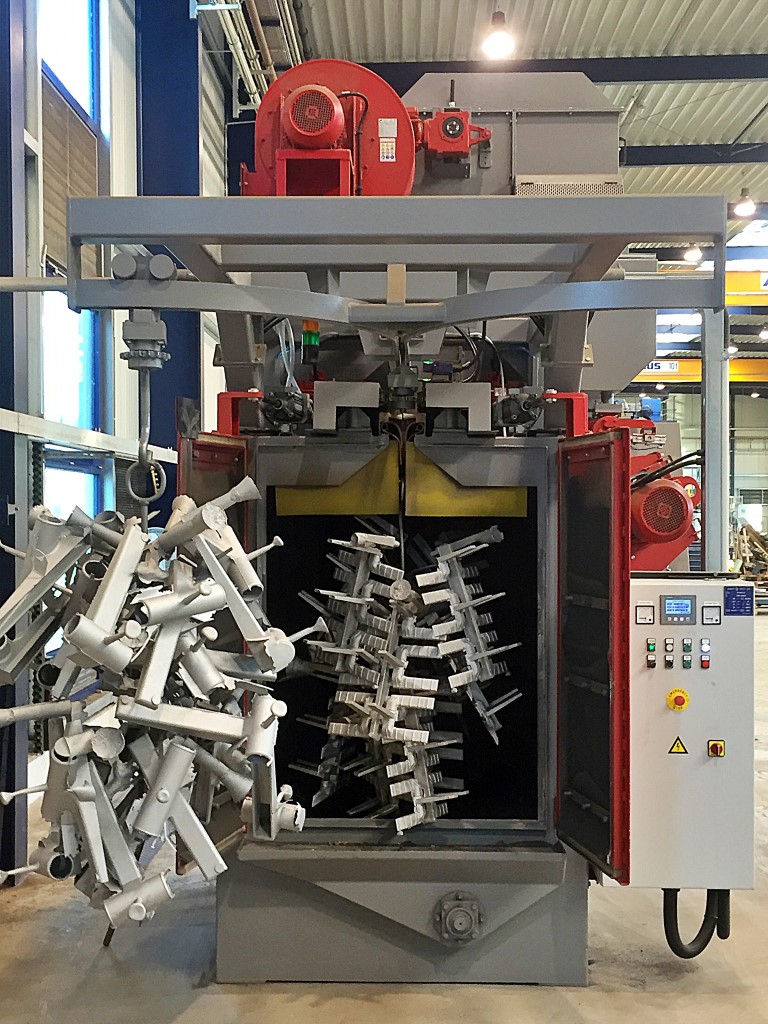

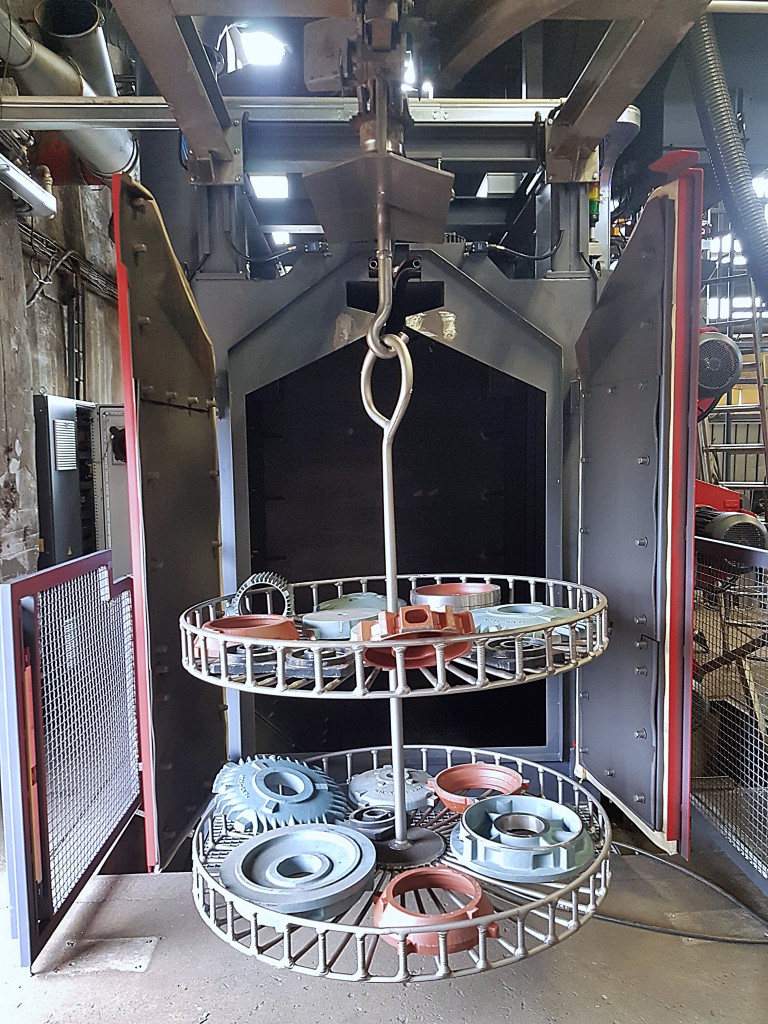

| Machine type | VK-600x1000 | VK-900x1500 | VK-1200x2000 | VK-1700x2200 | VK-2000x2500 | VK2500x3500 | VK-3000x4000 | VK-5000x5500 |

| Max workpiece dimensions diameter x height (mm) | 600 x 1000 | 900 x 1500 | 1200 x 2000 | 1700 x 2200 | 2000 x 2500 | 2500 x 3500 | 3000 x 4000 | 5000 x 5500 |

| Max load capacity of the hook (kg) | 500 | 1000 | 2000 | 2000 | 3000 | 5000 | 10.000 | 20.000 |

| Blasting wheel power (kW) | 2 x 4 | 2 x 7.5 | 3 x 7.5 | 3 x 7.5 | 4 x 11 | 4 x 15 | 6 x 11 | 7 x 15 |

| Blasting wheel diameter (mm) | 320 | 320 | 320 | 320 | 380 | 380 | 380 | 380 |

*Max hook load in case of manual operation is 1000 kg

*Especially for shot blasting machines of larger dimensions, a hook drive is usually used and the loads are higher.

*For all versions, the option of lift/drop is also possible.

*It is possible to install a magnetic separator and a vibratory conveyor, thereby changing the required installed power.

For additional information on different dimensions of shot blasting machine and the number of blasting wheels, please contact us. The machines listed are only an example of standard machines, but other adaptations and variants are available.